Embrace the grind.

Optimise & streamline your operations.

Optimising comminution circuits is essential for efficient and profitable mineral extraction. Our services are designed to empower mill operators and plant managers with practical, data-driven recommendations that enhance throughput, improve product quality, and minimise downtime.

Maximise efficiency with these tailored metallurgical solutions.

Plant Audits

A Plant Audit provides a pre-cursor to detailed modelling and simulation, focusing on maximising the efficiency and utilisation of key unit operations (e.g., crushers, mills, cyclones, and screens). It identifies parameters outside normal or recommended operating ranges and offers recommendations to optimise operating philosophy. An audit also includes a high-level review of operating strategies and control philosophy to enhance overall plant performance.

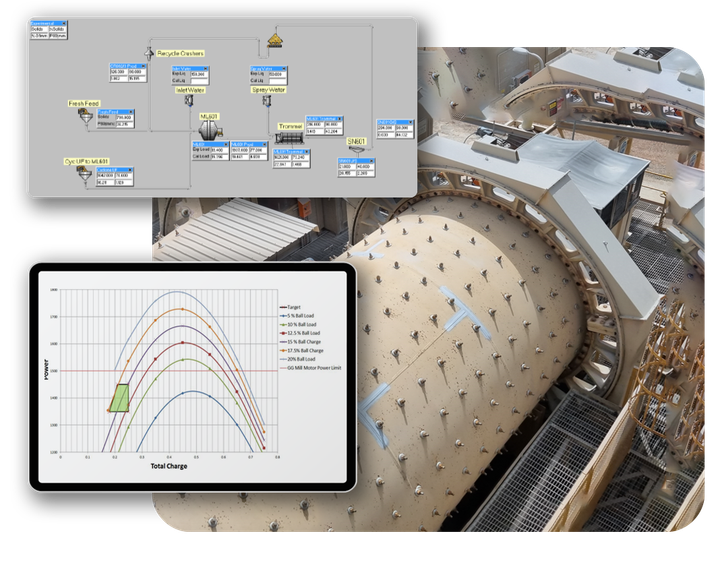

Simulation & Optimisation

Our Simulation and Optimisation service analyses the interaction of key unit operations to determine the optimum operating setpoints for the circuit as a whole. It also enables better prediction of effects on particle size distribution, slurry densities, and volumetric flow rates, ensuring a holistic approach to circuit optimisation.

Mill Liner Review & Design

We utilise a holistic approach for mill liner design which combines process expertise with practical design experience to provide our clients with mill liner designs which not only meet the required service life but improves mill performance. In addition to using traditional liner design tools such as trajectory modelling, DEM modelling, we also conduct mill performance reviews, process modelling and detailed wear assessments to provide the optimum lifter-liner solution.

What we’ve been working on.

The Toornado Metallurgy team has been privileged to work with over 100 mills of various sizes, ranging from 18ft to 40ft, across every continent. Our experience spans a variety of commodities and circuit configurations, allowing us to develop solutions tailored to unique operational challenges.

Our work includes studies covering SAG, AG, Ball,Rod and stirred mills, reinforcing our commitment to supporting the mining industry with thoughtful, data-driven approaches.

Smarter, more efficient mining starts here.

We prioritise your operational goals above all else, offering unbiased advice and strategies tailored to your unique challenges. Let Toornado Metallurgy help you unlock the full potential of your operations.

Unlock your plant’s full potential.

Contact us to optimise performance, boost efficiency, and achieve sustainable results.

GET IN TOUCH

NAVIGATE

All Rights Reserved | Toornado Metallurgy